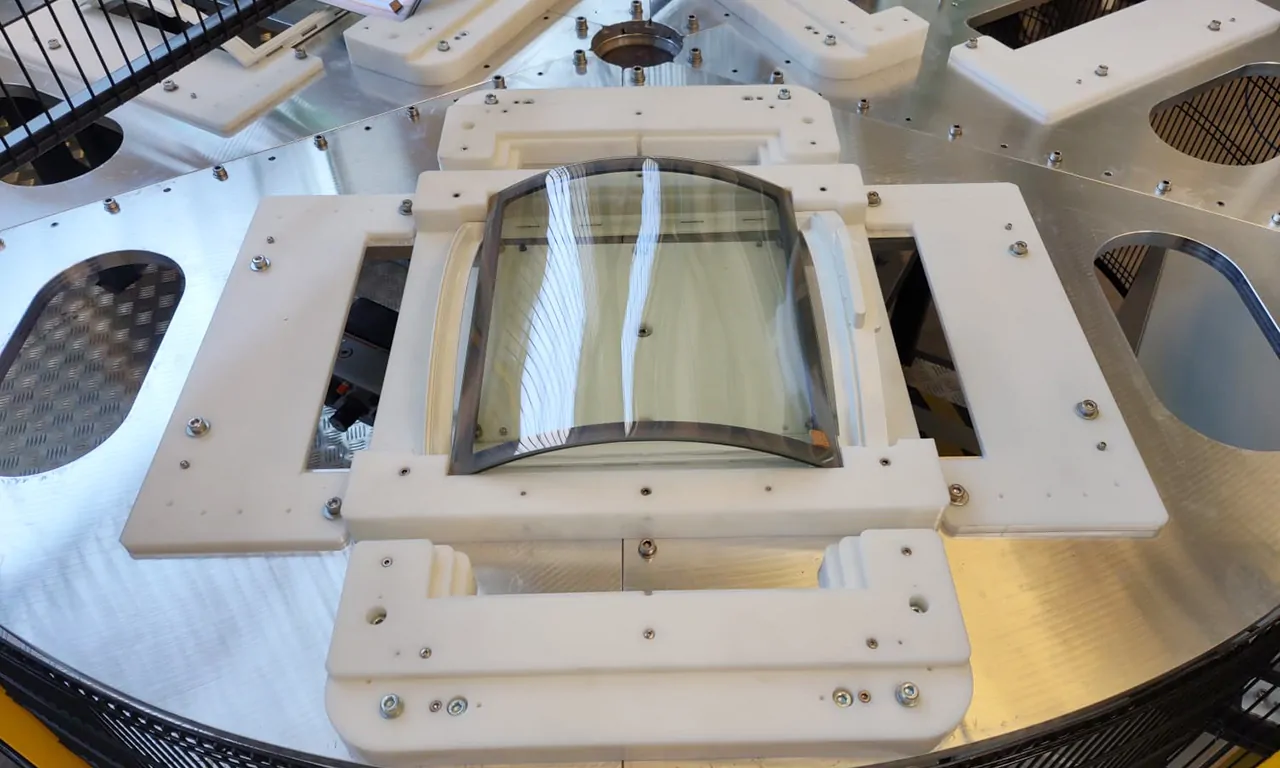

Robotized Rotary Table

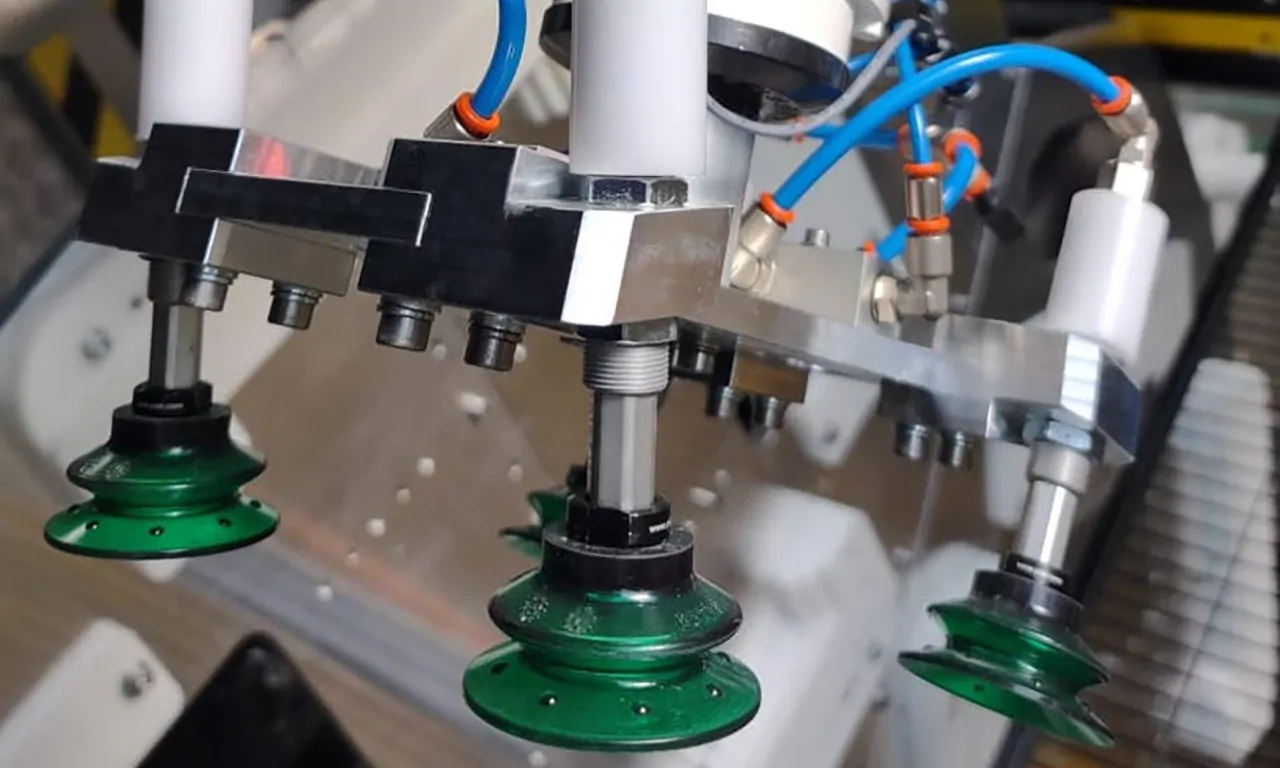

The customer's request was to automate the sealing and assembly process of some particular insulating glass. The glass product had to be handled with care, without smudging the two-component sealant and controlling the amount of material deposited. The solution was to use an isometric rotary table, loading, dosing, unloading. We have created an ad-hoc gripping hand with related antihalation suction cups to have a certain starting dosage position and maintain the cleanliness of the insulating glass. The PLC of control manages multiple recipes where information referring to the glass model, assembly strategy and all information and actions in exchange with the customer's MES are indicated.