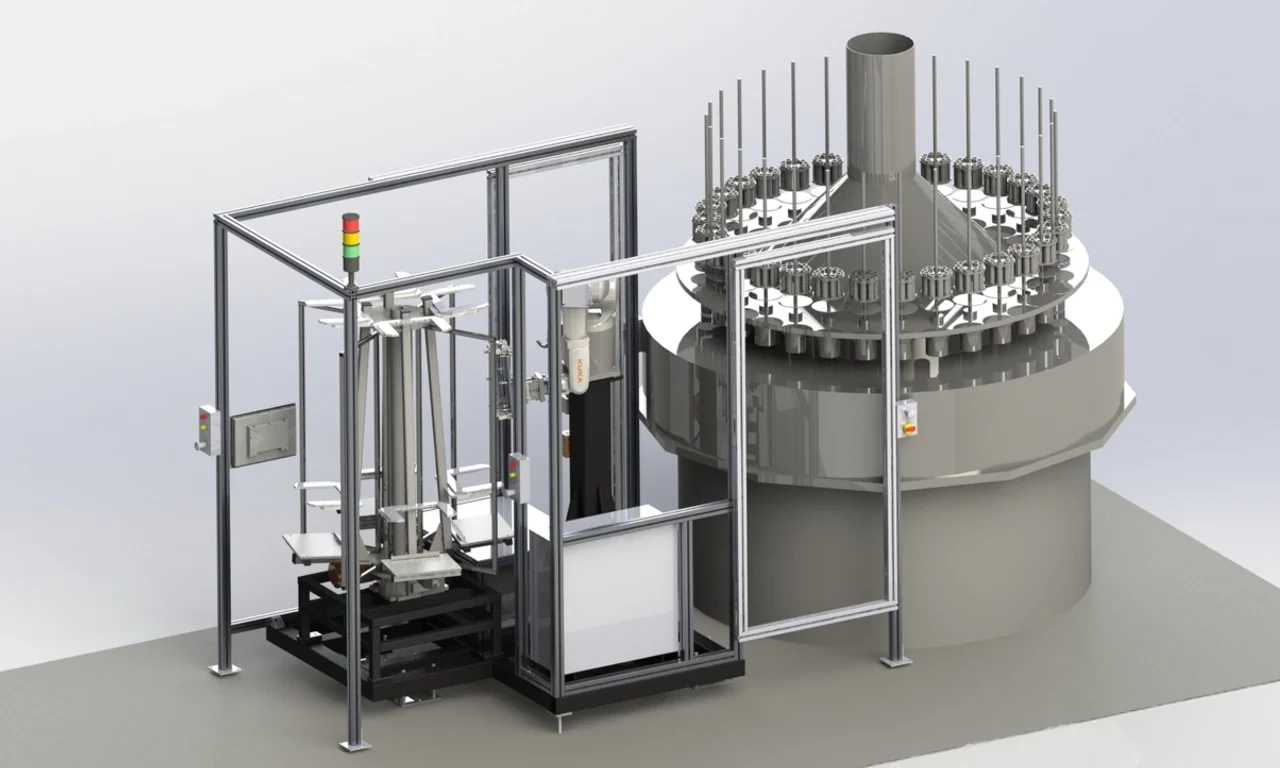

Automatic tube loader

Serial machine produced in several dozen units has the purpose of automatically serving glass tubes to rotary moulders of pre-existing vials.

The goal is to increase the efficiency of the forming machines by keeping them saturated at the maximum workload. The forming machine is also monitored and managed, through signals and alarms, in the event of malfunctions due to repetitive breaks in the spools caused by cloggings or mechanical out of position.

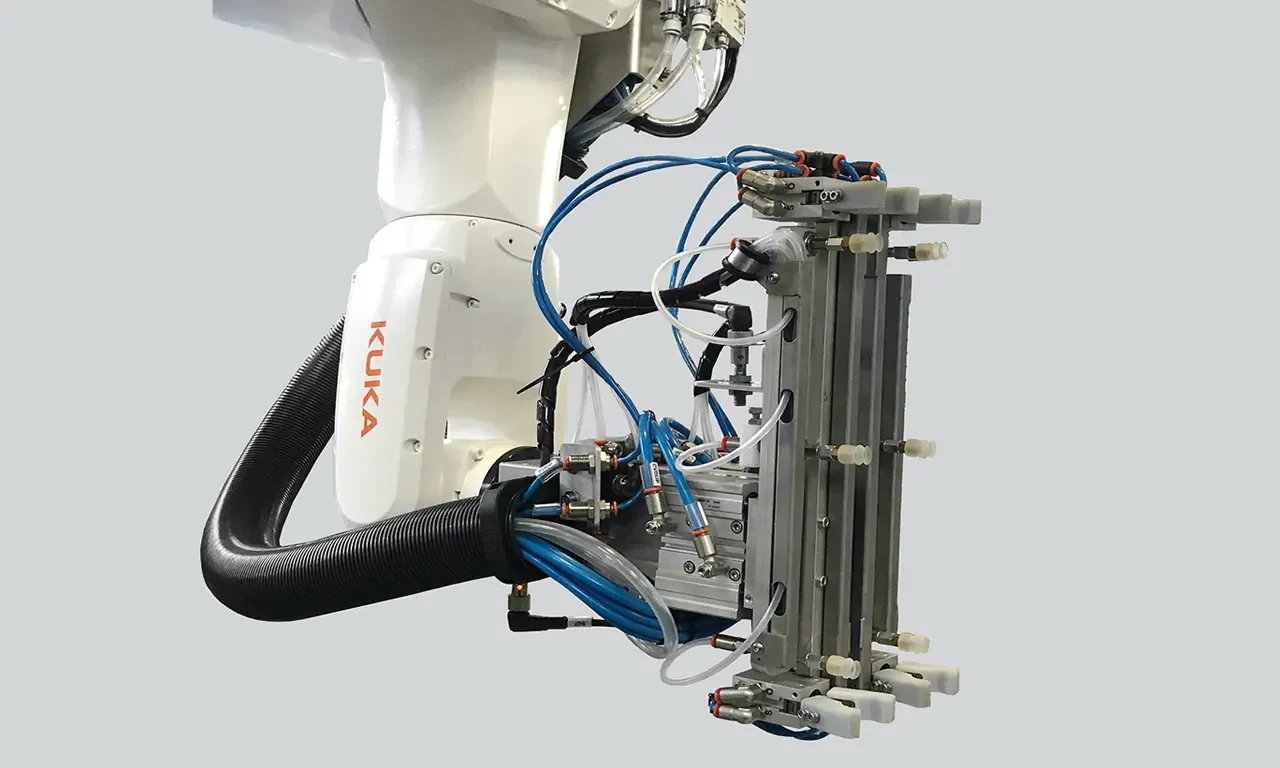

The solution is composed of a rotary table designed to contain 4 packs of tubes, and a robot that picks up two tubes at time with a double hand and, synchronizing with the rotation, loads the forming machine with a cadence of 150 tubes per hour maximum.

The PLC manages multiple recipes where the loading strategy, the characteristics of the pipes and all the information and actions in exchange with the customer's MES are indicated.