Robotized moulds lubrication

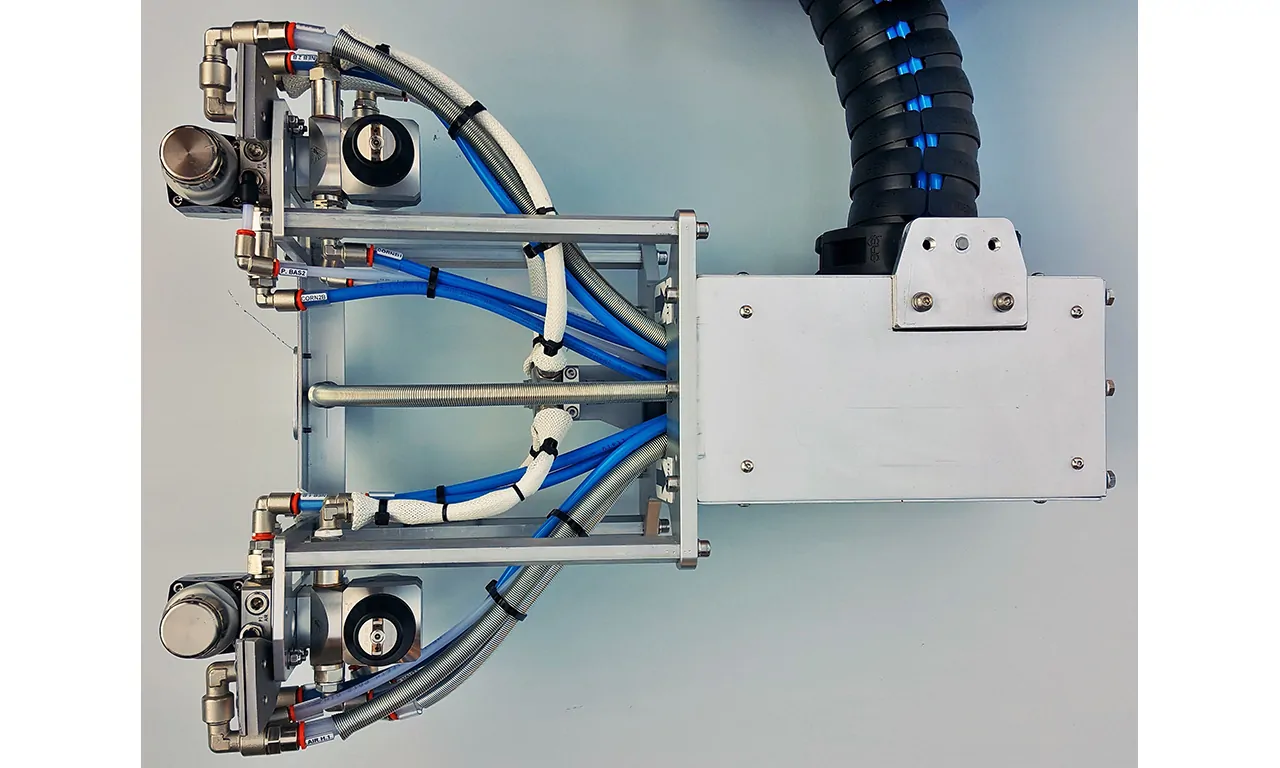

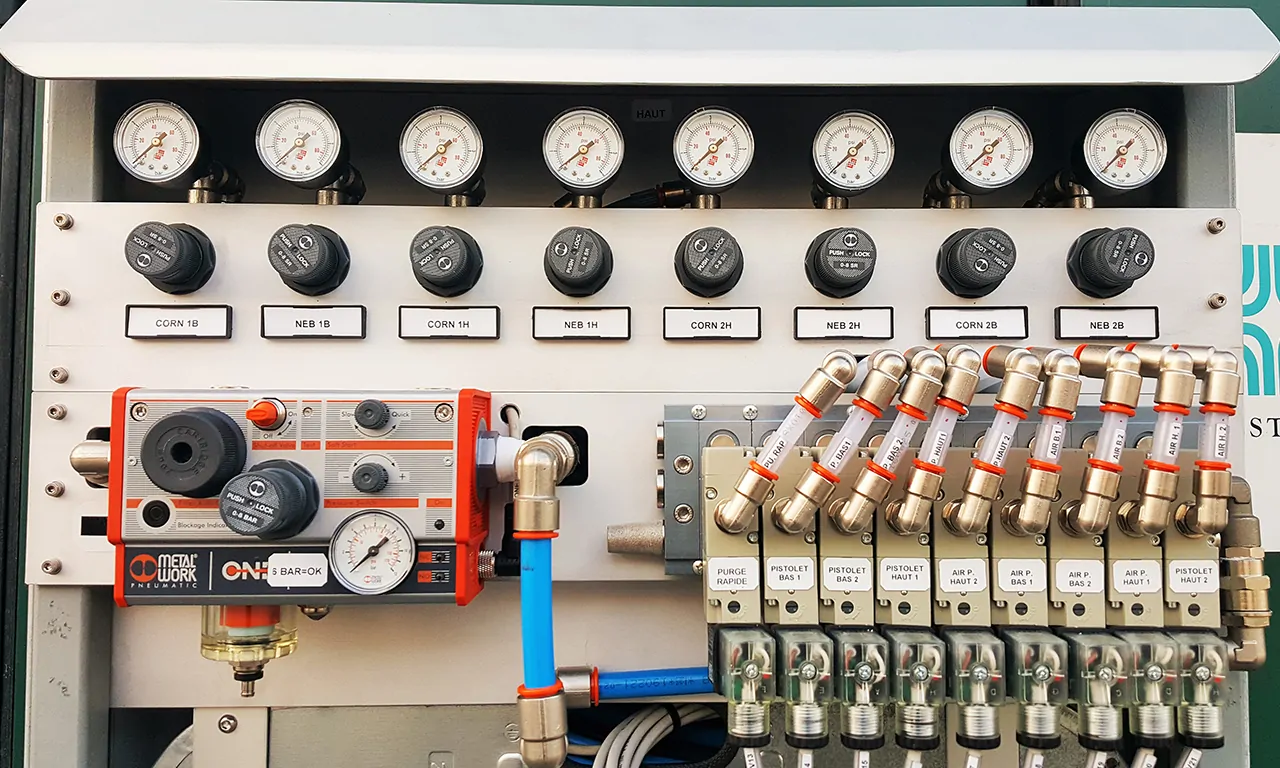

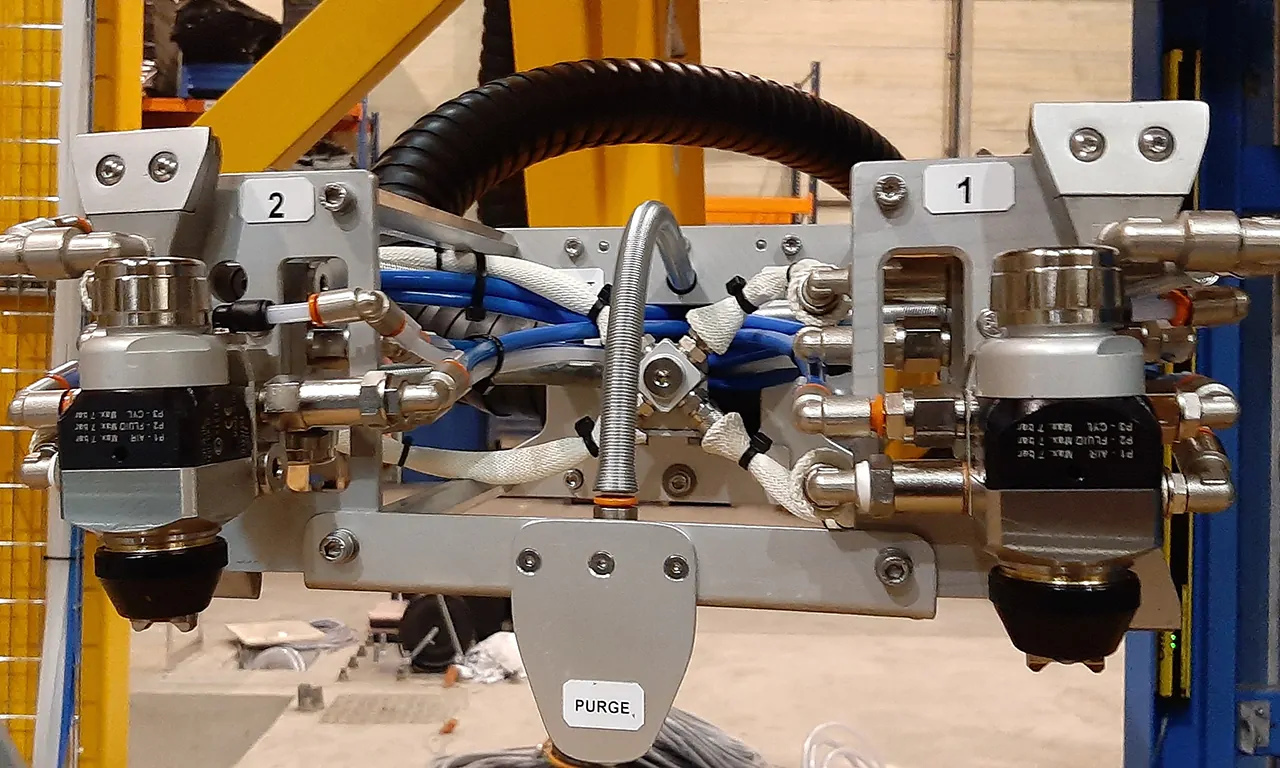

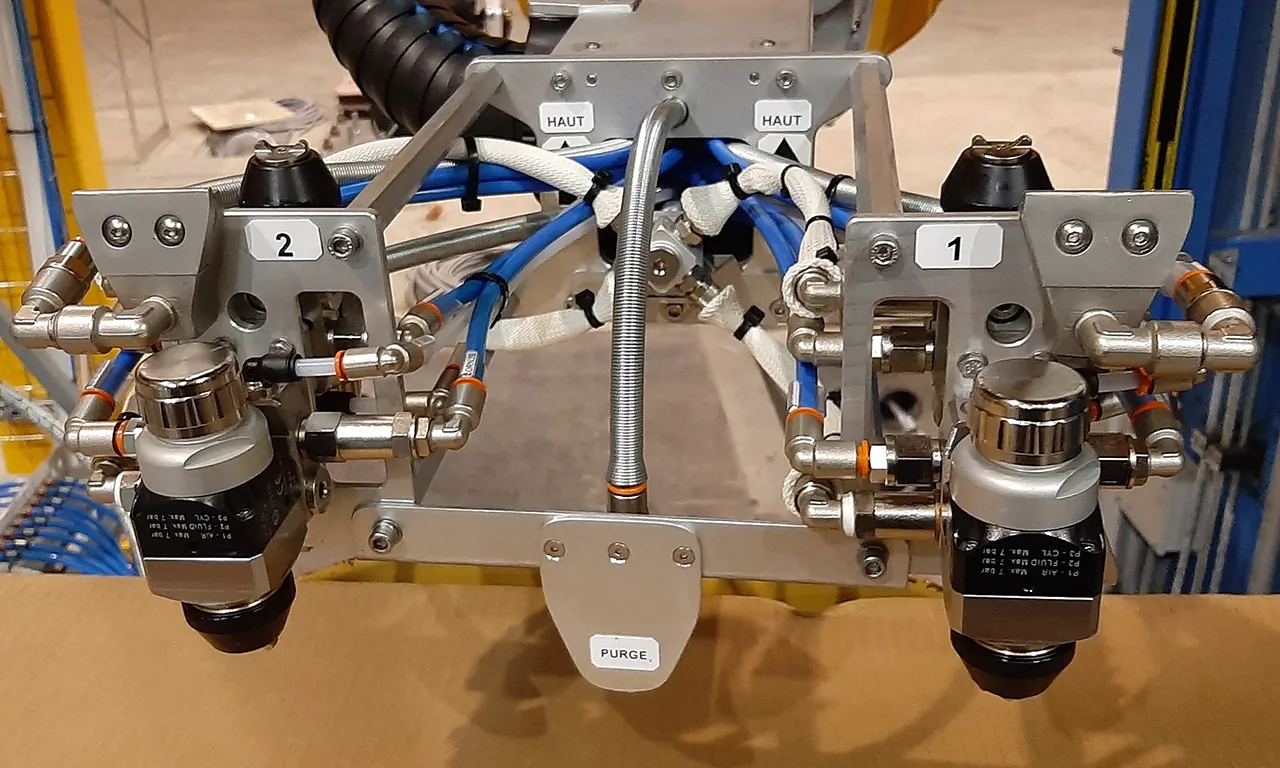

The application that we propose as an example is hot forging on a press. Two different types of materials can be used, graphite and/or boron. The system produces, with the desired material, the required mixture at the set percentage and is able to automatically wash the pipes up to the nozzles before changing the product. There are alarms for clogging of the guns, end of product, lack of air/water, safety devices and scheduled maintenance deadlines. On the hand of the robot, in addition to the guns, blowing nozzles are installed for cleaning the mould; it is possible to change the air jet, pressure, flow rate and size of the spray pattern for each gun. The system is remotely controllable and provides for different recipes and robot paths for each mould. In this application the integrated robot was provided by the customer.